At our research institute, we are dedicated to developing state-of-the-art machine learning technologies tailored for practical applications. If you’re seeking a more efficient and accurate approach to inspections, our CAD-Based Visual Inspection solution is here to help.

Introducing CAD-Based Visual Inspection

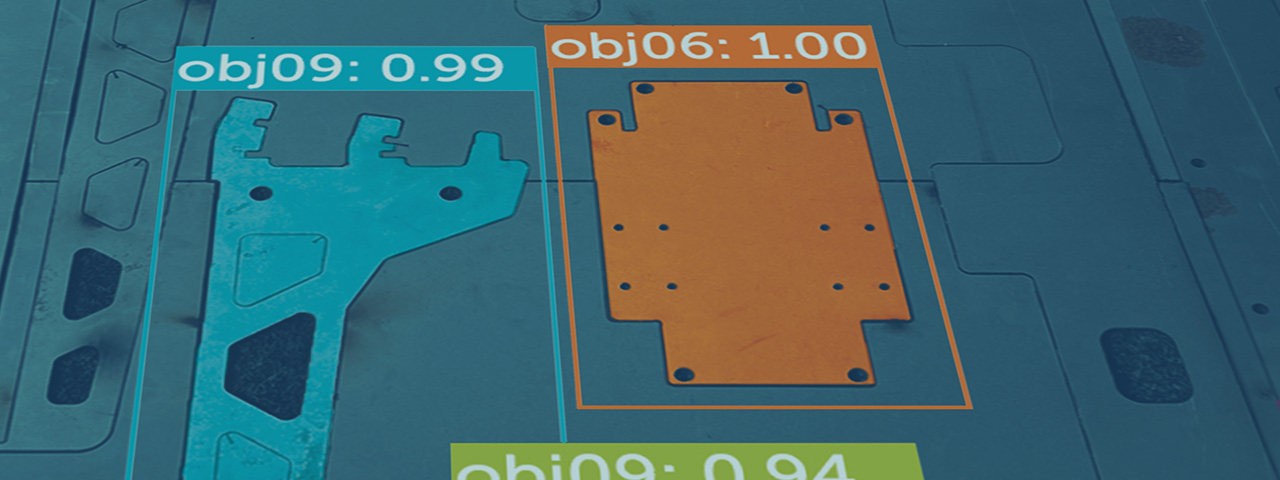

We utilize advanced machine learning algorithms alongside your CAD models to generate synthetic training data, improving the effectiveness of neural networks for visual inspection tasks.

Key Benefits:

- Reduced Human Error: Minimize inaccuracies associated with manual inspections, enhancing reliability.

- Increased Efficiency: Experience faster analysis and processing for a more streamlined workflow.

- Adaptable Solutions: Our technology performs well in dynamic environments, ensuring robust results.

- User-Friendly: Eliminate the need for extensive manual configuration and data labeling with our approach based on synthetically trained machine learning.

Sample Use Cases:

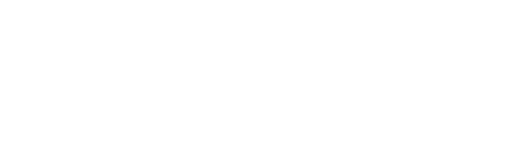

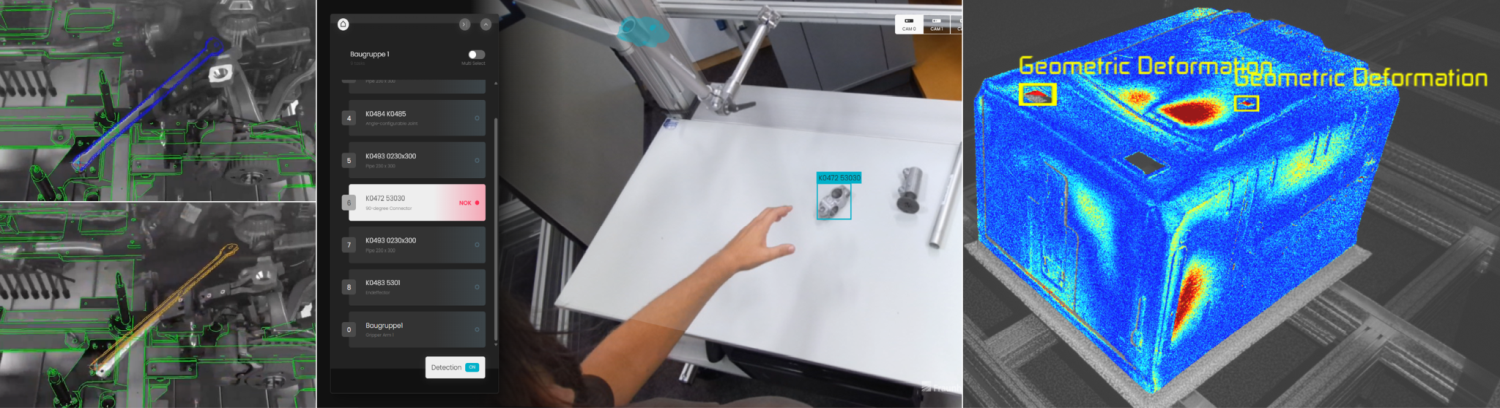

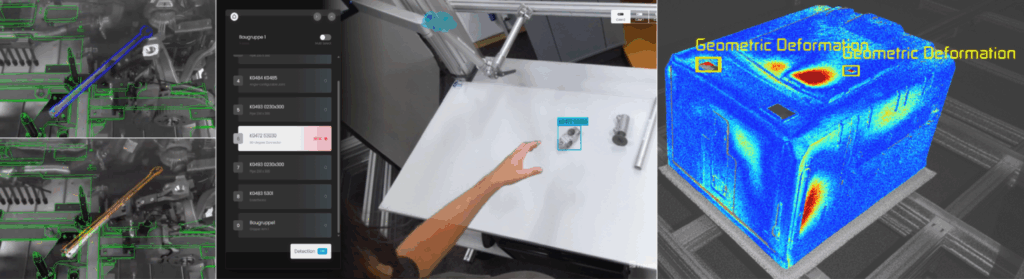

- Assembly Inspection:

Our solution automates the inspection of assembled products, ensuring that components are correctly placed and meet quality standards. By analyzing CAD models, the system can quickly identify misalignments or missing parts, reducing the risk of defects in the final product. - Worker Assistance:

Enhance worker productivity and safety with our visual inspection system. The technology can provide real-time feedback to workers during assembly or manufacturing processes, alerting them to potential errors and offering guidance based on CAD specifications. This not only improves efficiency but also fosters a safer working environment. - 3D Defect Detection:

Detecting defects in 3D objects is crucial in various industries. Our CAD-based visual inspection leverages machine learning to analyze 3D models and identify imperfections, such as surface flaws or structural inconsistencies. This capability ensures that products meet stringent quality requirements before they reach the market.

Partner with us to leverage cutting-edge machine learning technologies and upgrade your inspection process. Contact us to learn more about how we can support your needs.

Do you have any questions? Feel free to get in touch!

The Fraunhofer Institute for Computer Graphics Research IGD supports companies in analyzing specific application cases and offers customized solutions for efficient quality control.