We are committed to advancing the use of augmented reality (AR) and AI in manual assembly processes. Our focus is on exploring and developing a range of capabilities that enhance the efficiency and accuracy of assembly tasks, drawing from a collection of innovative projects designed to address diverse industry needs.

Capabilities:

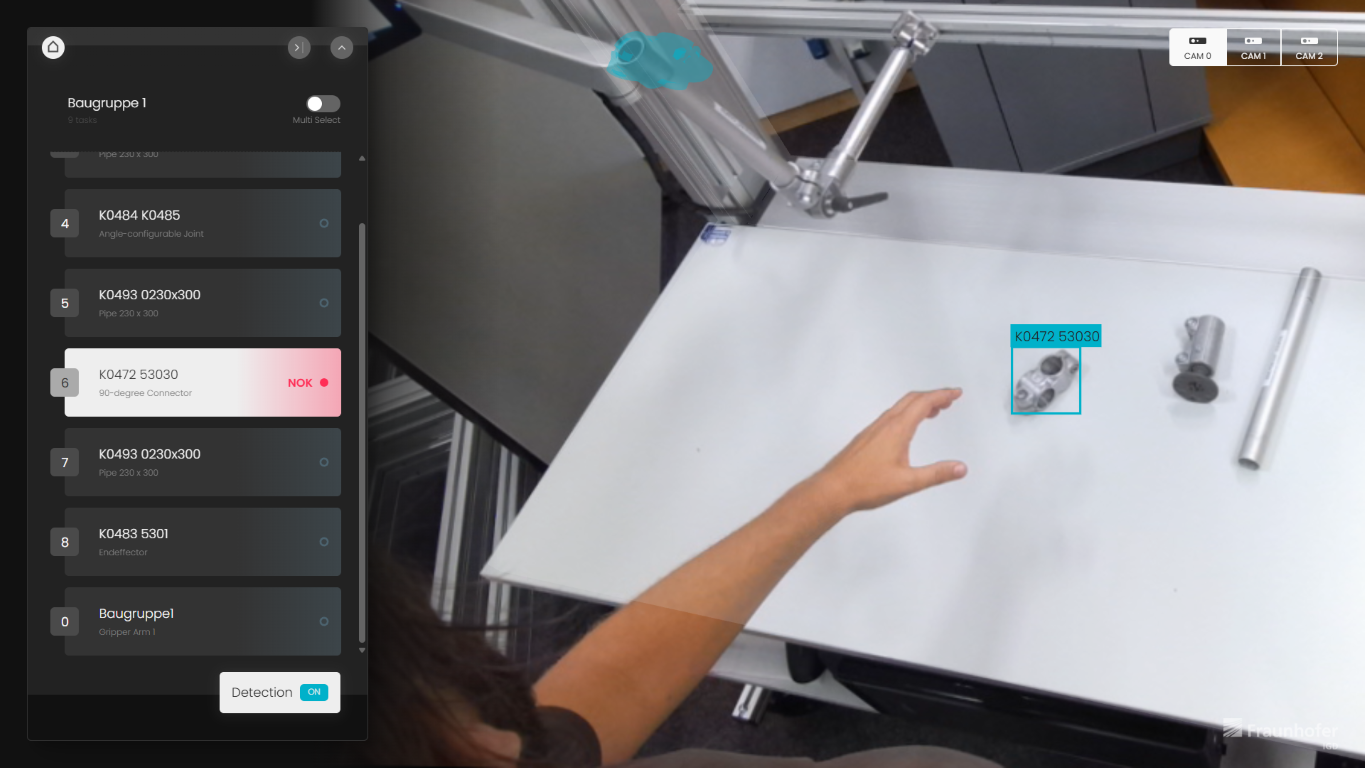

- User Guidance: ours systems provide intuitive support for operators by overlaying digital information onto the physical assembly environment.

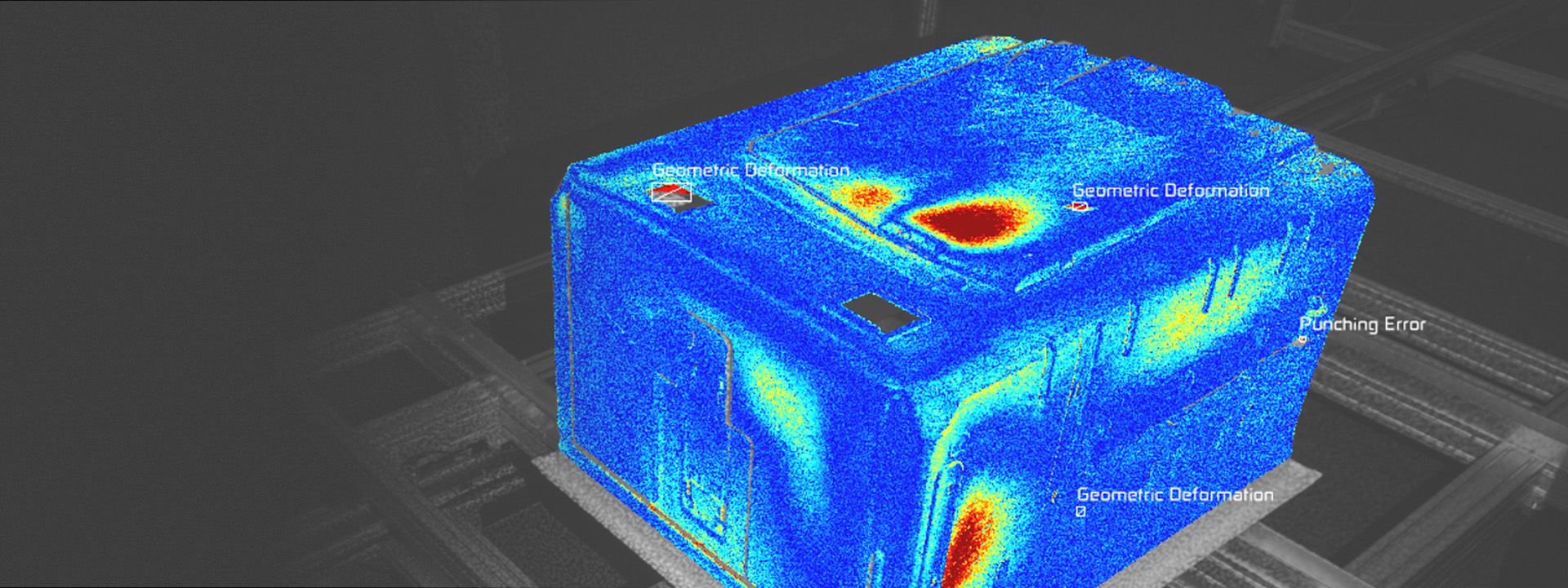

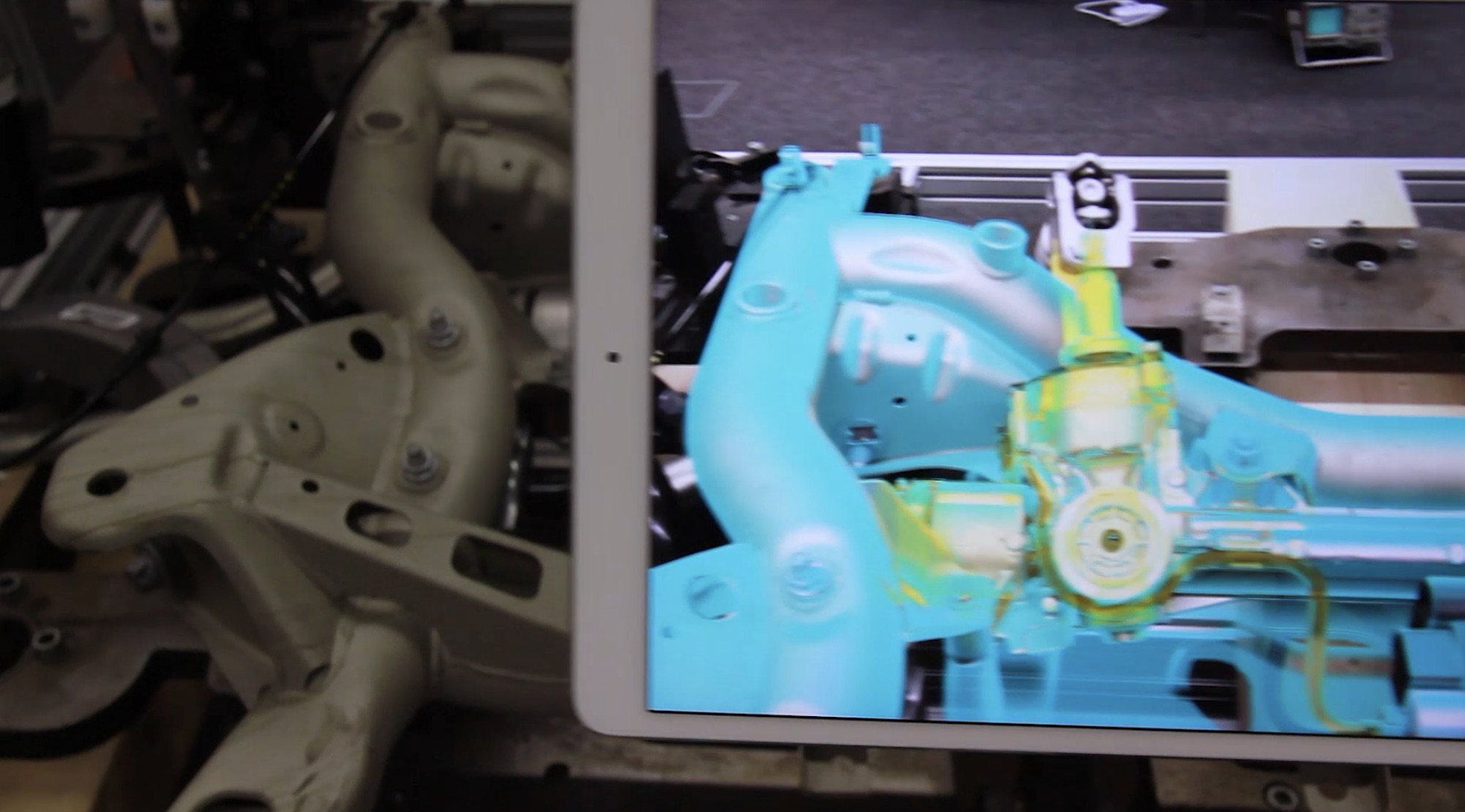

- Real-Time Feedback: our systems enable immediate automatic inspection of assembly accuracy, helping ensure alignment with design specifications.

- Expert Collaboration: our systems can provide real-time communication with remote experts, allowing for actionable instructions and insights during the assembly process.

Benefits:

- Increased Efficiency: streamline assembly processes, reducing time and minimizing potential errors, thereby enhancing productivity.

- Enhanced Accuracy: By integrating real-time feedback and expert guidance, we support higher quality in assembly outcomes, leading to fewer defects.

- Adaptability: Our work is geared towards creating flexible solutions that can be tailored to workstations with fixed screens or mobile and head-mounted XR devices, accommodating different assembly environments.

Fraunhofer IGD is dedicated to leveraging augmented reality and AI in assembly processes. Through our diverse projects, we aim to develop customized solutions that meet the unique challenges of our clients, fostering innovation and efficiency in modern manufacturing.

Do you have any questions? Feel free to get in touch!

Related topics