Augmented Reality (AR) and Machine Learning are changing assembly processes in manufacturing by improving how human workers engage with complex tasks. By integrating digital information with the physical environment, AR-guided systems help streamline workflows, shorten training times, and enhance accuracy. This approach not only simplifies the assembly process but also ensures that tasks are performed with a higher degree of precision.

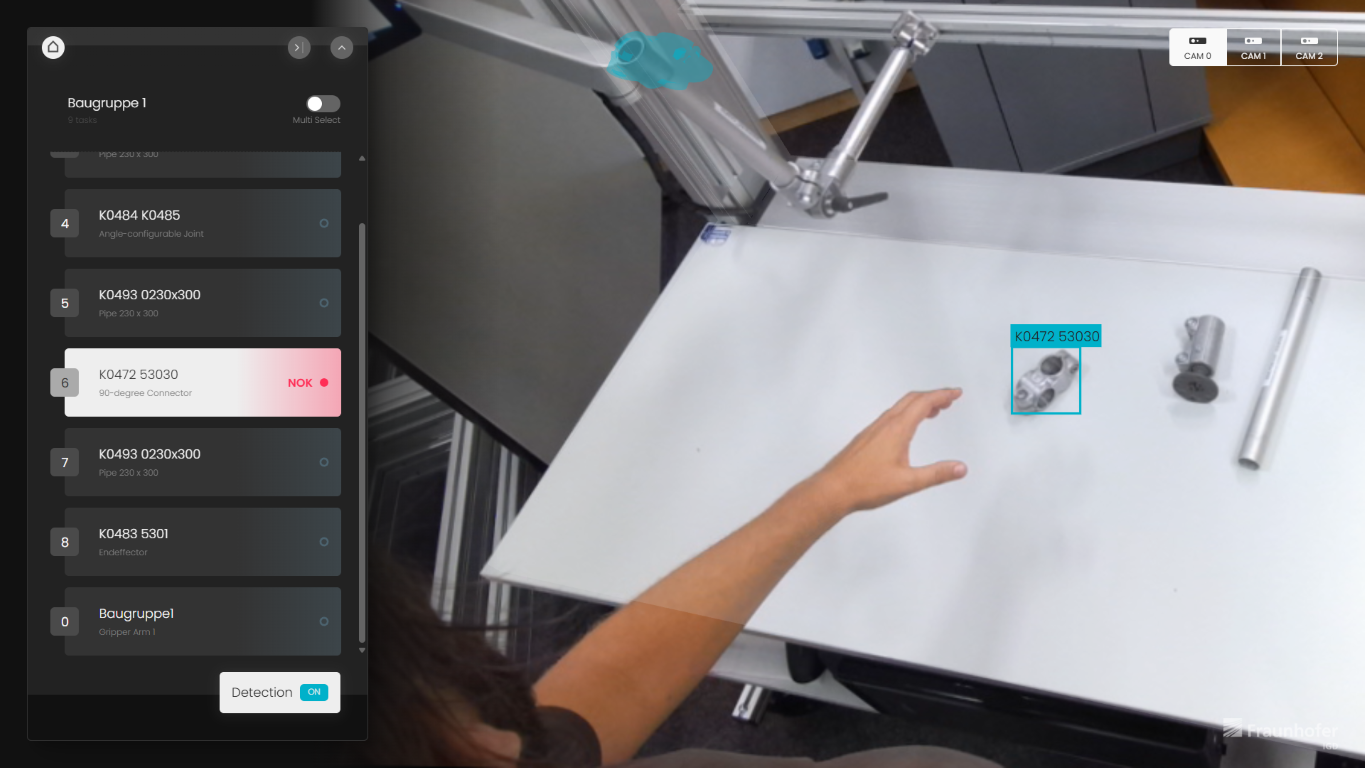

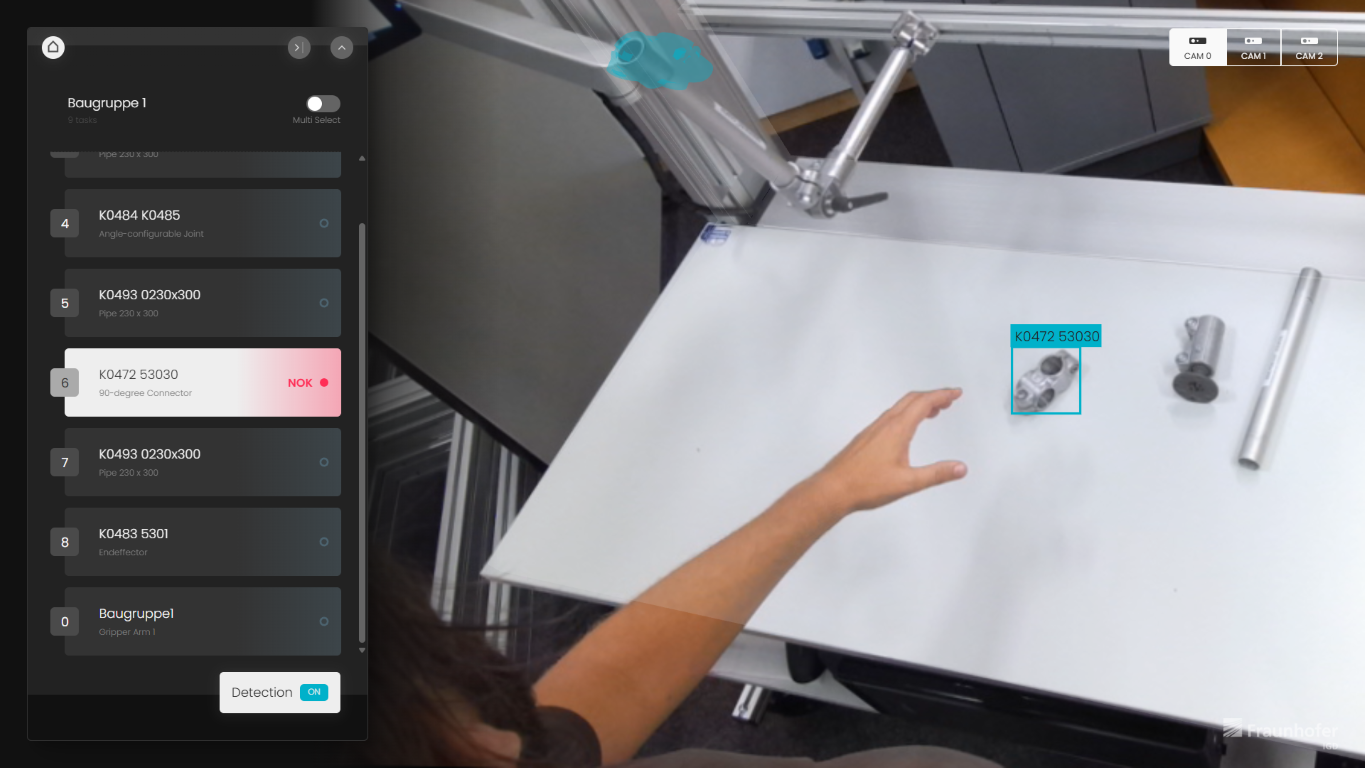

Based on CAD specifications, the system automatically detects the parts to be assembled and intuitively directs workers on which part to pick next. By overlaying the target position onto a live camera image, the assembly process is significantly simplified and supported. Additionally, the system performs automated inspections of the assembled parts to ensure completeness and correct positioning. With the capability to utilize multiple cameras from different perspectives, the system guarantees accurate detection, even in the presence of potential obstructions. This approach replaces traditional 2D assembly instructions, allowing workers to seamlessly translate information into the three-dimensional workspace.

In summary AR-assisted-assembly has the following benefits:

- AR-guidance for more efficient workflows and less time for training workers.

- CAD-based training and authoring, no manual training of the system is required.

- Automated inspection of existence and position of parts and direct feedback to avoid defective assemblies.

With the AR-based assembly workstation, complex product setups are efficiently supported and simultaneously verified against CAD specification. The system thus replaces 2D-assembly instructions which require human workers to transfer 2D information into the 3D world.

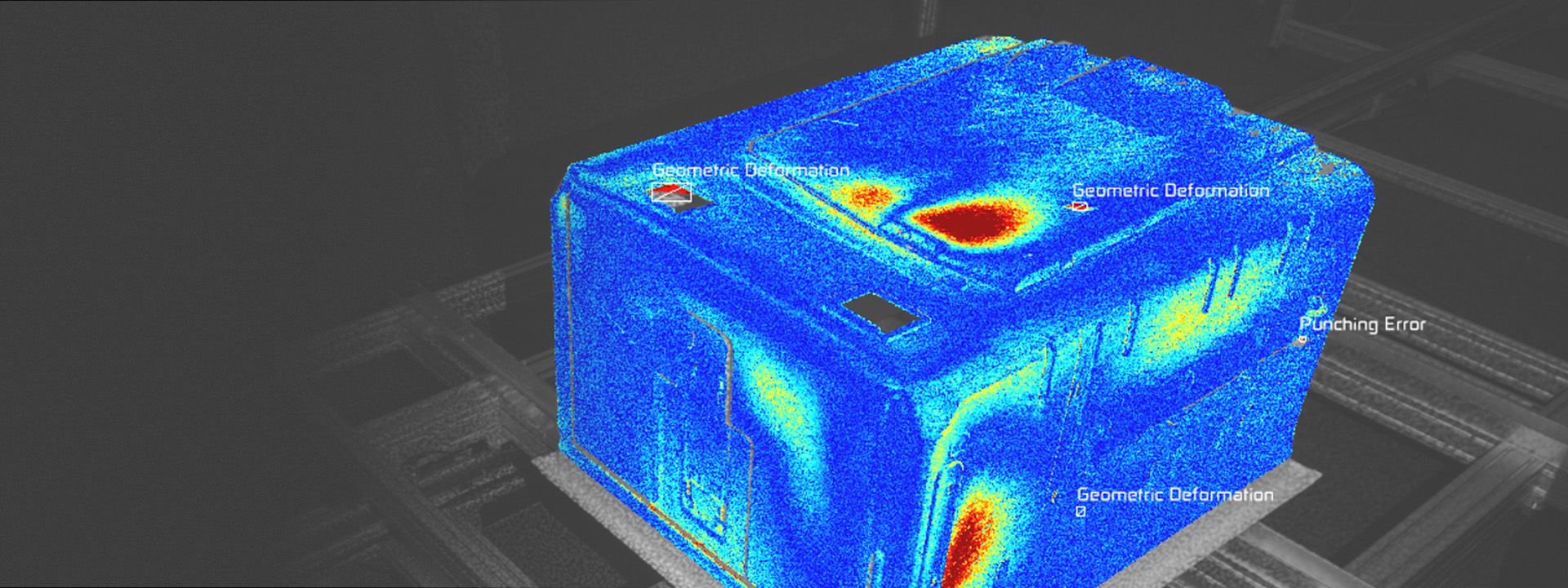

The system is highly modular and could be extended with features like

- More involved inspection logic, e.g. surface defect detection or inspection of the geometry of individual parts.

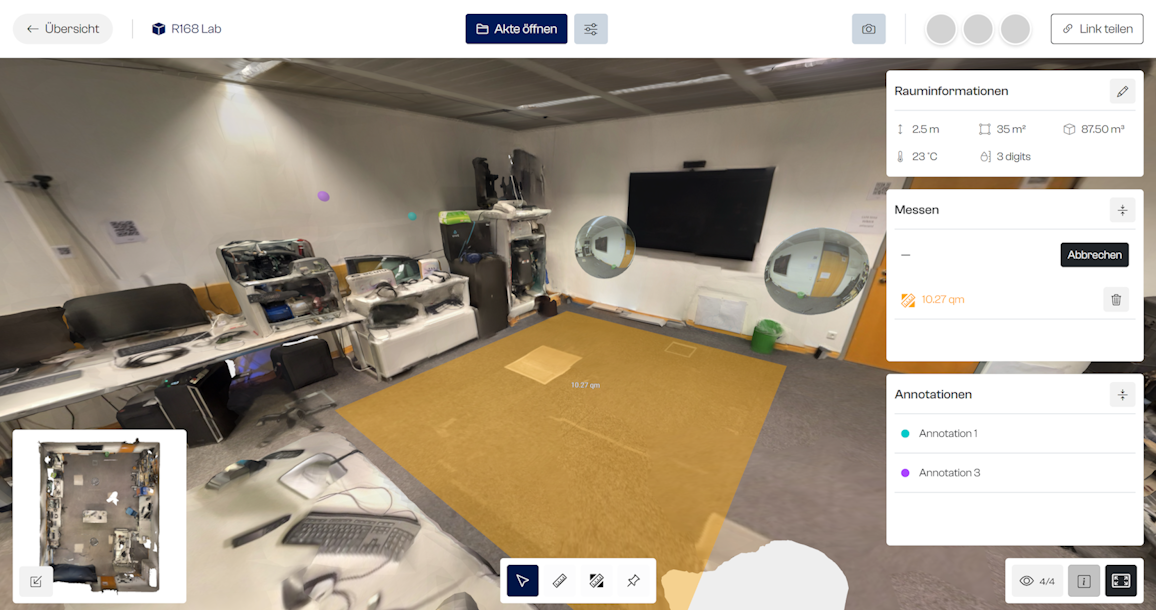

- Remote connections for getting support from distant experts or reviewing assembly tasks and inspection results cooperatively.

- More modes of visualization, e.g. through head-mounted-displays or hand-held devices.

Fraunhofer IGD is looking forward to getting to know your use-case for AR-assisted-assembly tasks and developing a solution specifically tailored to your needs!