Our research group specializes in CAD-based visual quality inspection, developing cutting-edge solutions to ensure the integrity and quality of manufactured goods. We integrate advanced Artificial Intelligence (AI) with synthetic training based on Computer-Aided Design (CAD) models to create fast, reliable, and deployable inspection systems.

Our Approach: AI with Synthetic Data

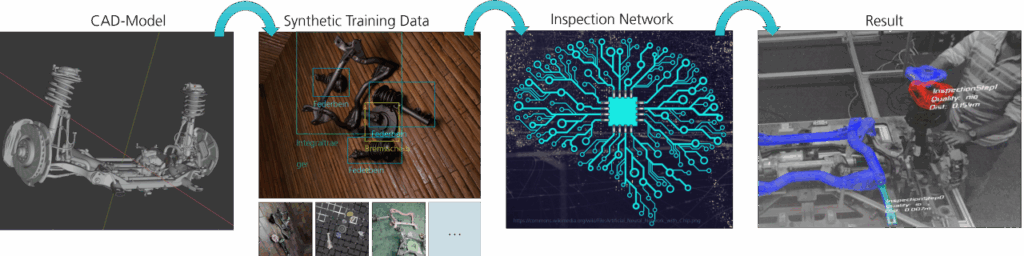

Our primary research avenue leverages AI models trained on synthetic data.

By utilizing CAD models, we can generate vast, highly realistic synthetic datasets to train robust AI models, particularly for object- and defect-detection tasks, without the need for extensive, costly, and time-consuming manual data annotation from real-world production environments.

While our main focus is on AI, we maintain flexibility and, where appropriate, integrate classical rule-based algorithms to ensure the most reliable and efficient inspection solution for a given task.

Key Use Cases

Our work targets three critical areas of industrial quality control:

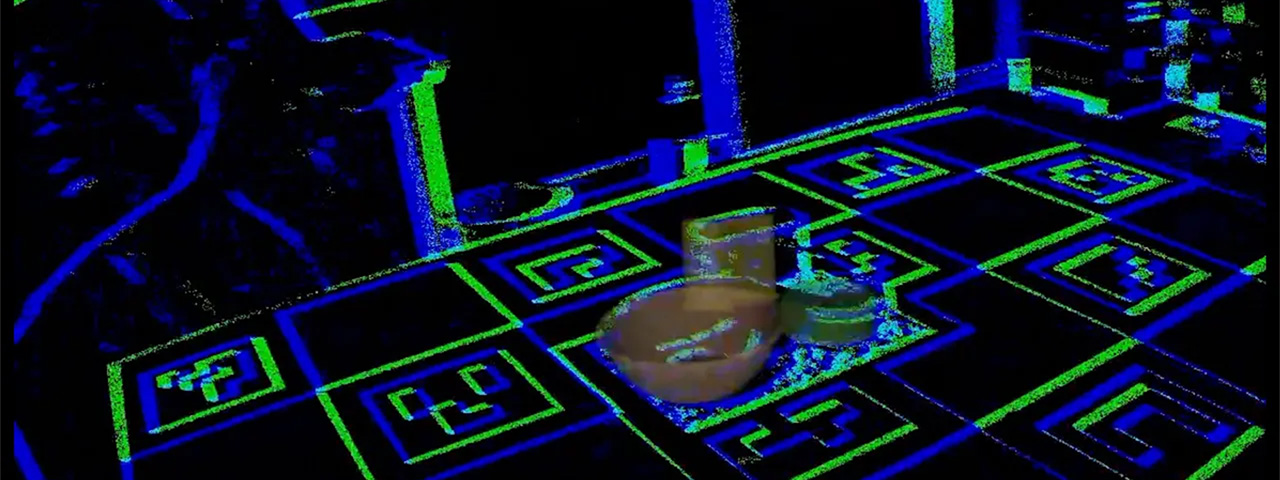

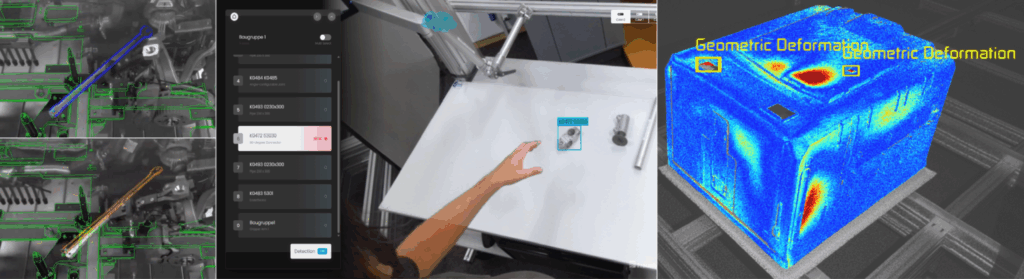

- Assembly Verification: We develop systems that inspect for correct assemblage by detecting individual assembly parts within an image or scan. By comparing the detected parts’ position, orientation, and variant against the CAD specifications, we can verify the existence and correct placement of all components, ensuring the product is put together according to design.

- Surface Defect Detection: We tackle the challenge of identifying surface defects, such as scratches and blemishes. Our core competence here is deploying synthetically trained AI models that are specifically designed to spot these subtle defects with high accuracy, leading to reliable quality assurance.

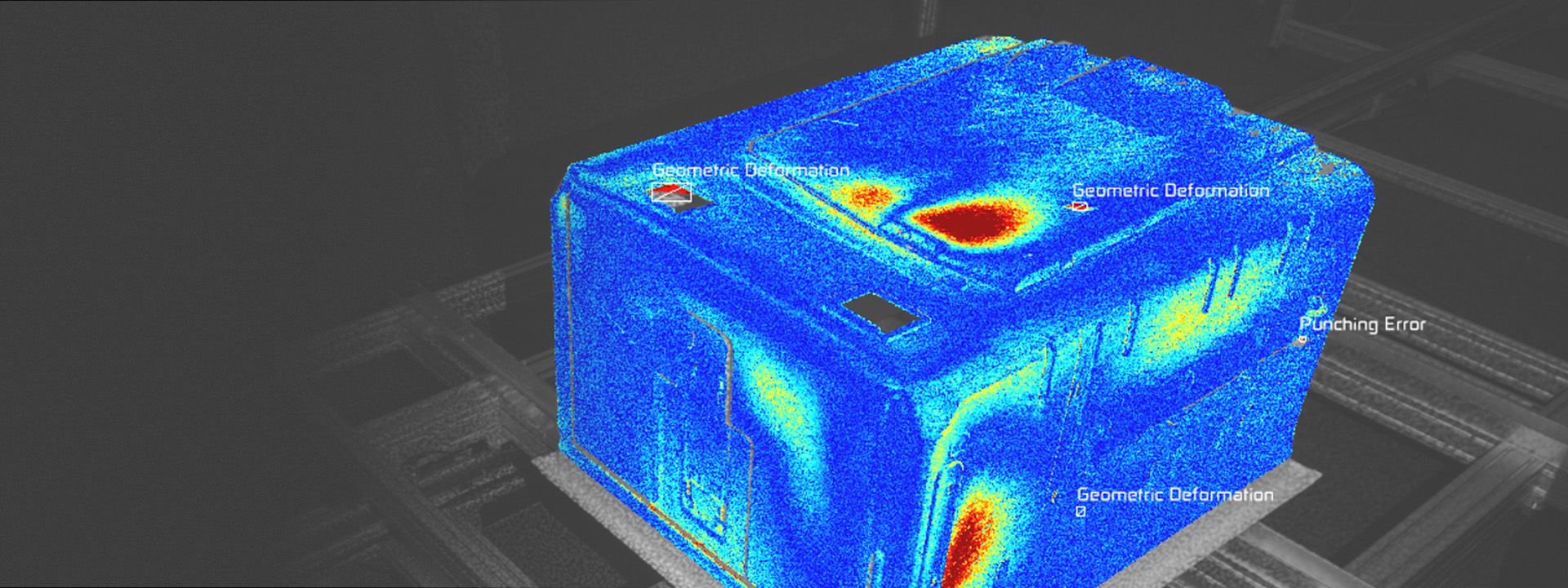

- Geometric Correctness: We focus on verifying the overall geometric correctness of the manufactured part by comparing high-resolution 3D scans directly against the CAD references, ensuring adherence to specified dimensions and shape tolerances. This process also detects and reports geometric defects such as warpage and positional errors of holes or cuts, so any nonconformities are identified and addressed.

Focus on Edge Computing & Inline Solutions

A key differentiator of our research is the commitment to creating practical, deployable, and cost-effective industrial solutions.

- Inline Solutions: Our primary goal is to develop inspection systems that can operate at a speed that keeps up with the production rate, enabling true inline quality control without creating bottlenecks.

- Edge Deployment: We specialize in developing software and utilizing hardware capable of running our complex models on the edge (i.e., directly on-site and near the production line). This strategy is crucial for cost efficiency, enhanced data security and safety, and greater reliability.